Platform System

A platform system gives you the flexibility to customise and develop applications more suited to your factory.

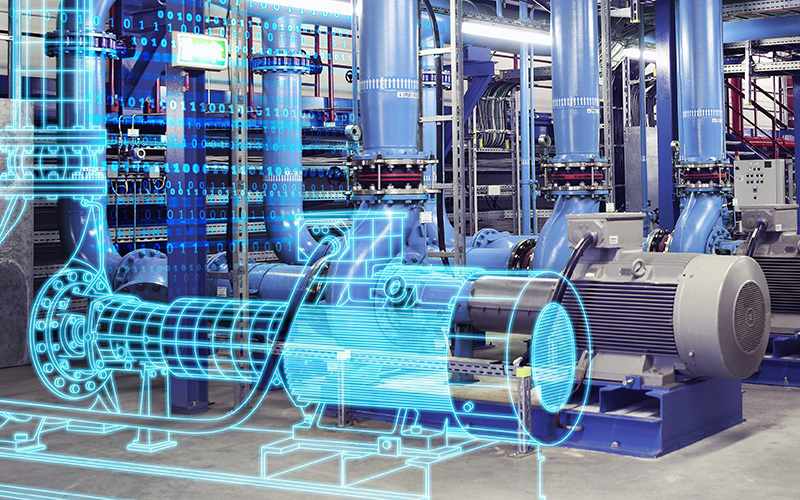

Introducing Quad Industrial IoT Solution. A simple plug and play tool, cross compatible with any industrial machinery regardless of how old it is. With the help of Internet of Things (IOT) a suite of sensors can be plugged into the physical system that can continuously communicate data in realtime of various ongoings to the remote cloud server, and the digital twin can be programmed to behave conditionally. This gives a realisation of the actual shop floor on a virtual desktop.

In the rush of implementing Industry 4.0 we often miss out on developing the crucial building blocks on the revolution. The following our understanding and foundation of Industry 4.0

Data Acquisition layer is a primary layer which is built in sync with the factory infrastructure. It is a single, central repository of all the incoming data. The data is further processed, organised and warehoused in the appropriate containers for further processing. This layer serves as a data bank. Appropriate security and backup mechanisms are implemented to ensure its integrity.

This is the second layer where basic reports are generated in realtime basis and monitored. This layer throws light on the true picture on the shop floor. Standard reports are generated which could eventually evolve into customised reports using differential formulas and algorithms. Different teams shall create their own dashboards and reports based on their specific requirements.

Once the stakeholders of every department are well familiarised with digitalisation and have started using it for their day to day activities, AI & RPA are introduced. Artificial Intelligence based predictive analysis can be put to use based on data trends. RPA Bots can be configured to automate all the robotic processes followed each day. This helps improve over all efficiency across the factory.

While it is a common practice to relay information using different data loggers, we strongly believe every factory requires a customised modular approach.

A platform system gives you the flexibility to customise and develop applications more suited to your factory.

Real-time awareness of various ongoings of your shop floor. Data availibility at the time it is required is our moto.

Analytics from the basic production trends to understanding return on capital invested.

AI based predictive analysis, Go beyond maintenance predictions and downtime predictions with Quad AI

Our platform approach has enabled us to make spin off modular API bundles which can be used to integrate with any ERP

Bid Farewell to the long hours spent on data entry! Eliminate the absolutely redundant, non productive processes from your factory.

Customise your reports as per your requirements. Every individual can customise their own dashboards.

Tired of managing all those heavy servers? Adopt to our Cloud based Platform as a Service.

Any digitalisation activity is incomplete without first developing a digital twin of the factory.With the help of Internet of Things (IOT) a suite of sensors can be plugged into the physical system that can continuously communicate data in realtime of various ongoings to the remote cloud server, and the digital twin can be programmed to behave conditionally.

We are powered by Amazon Web Services, One of the most secured infrastrucre available. To take other measures, we have our own encryption algorithms to protect your data.

Quad Data streams are encrypted end to end; Your data can only be visible when you open the dashboard. It is saved on our databases in an encrypted form.

We take data security very seriously. Every flowing information on our platform is passed through a layer of firewall and filteration on our API level.

We have a suite of features to simplify your business processes. Lets understand a few of them enlisted below

Talk to us to use our platform for your analytical and process automation tools. Integrate with Quad Platform, bring your factory online now.